When your hydraulic system is playing up, it doesn’t always mean there’s a huge or expensive problem. In many cases it’s simply that your seals have deteriorated and are leaking.

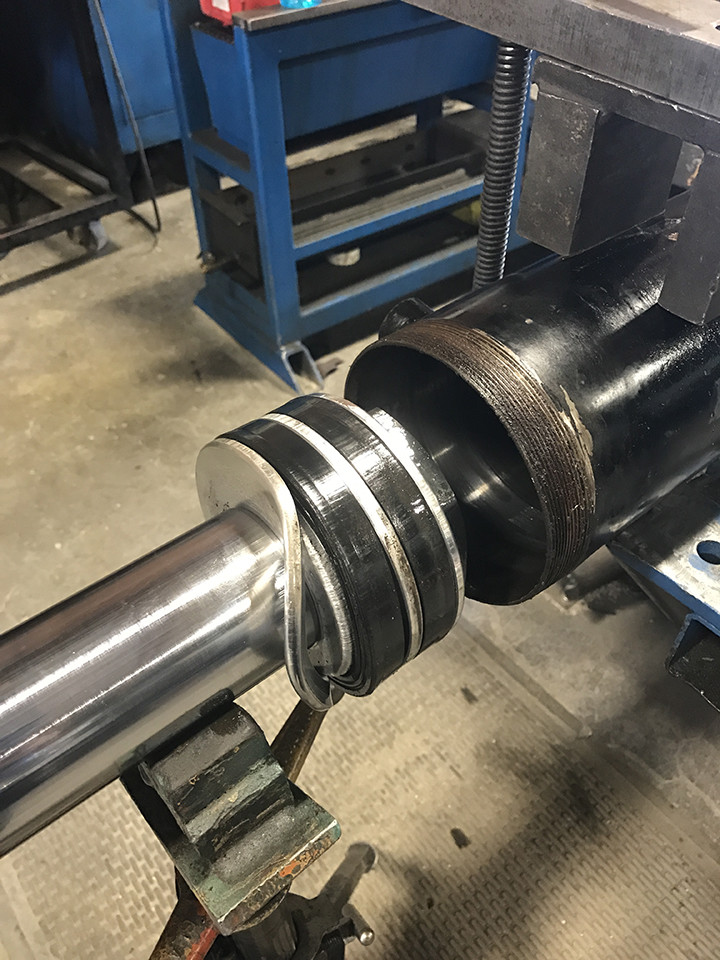

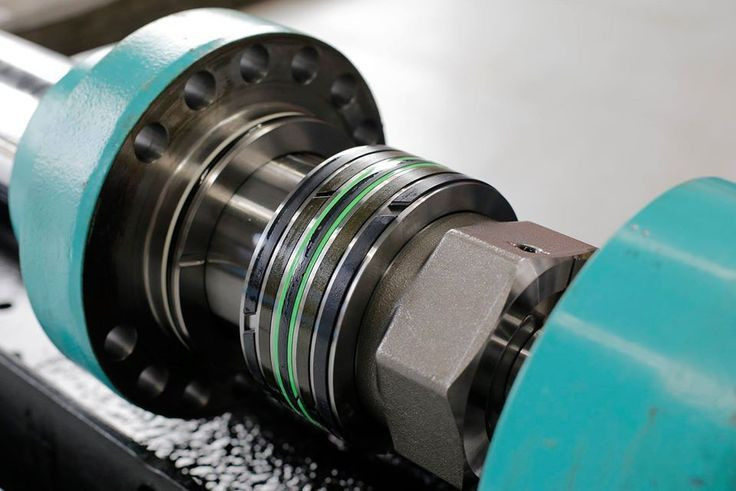

Hydraulic cylinder seals are used to seal the opening (clearance gap) and prevent leakage between various parts of a hydraulic cylinder. These often-overlooked components are one of the most important parts of your hydraulic system — in fact, without those seals, your systems wouldn’t work at all. There are numerous types of seals, however most fall into two categories:

Dynamic seals – seals between components in relative motion

Static seals – seals between two fixed components without relative motion, normally the piston and piston rod, or between the head and the cylinder bore tube.

Because hydraulic seals are exposed to a variety of tough working conditions such as significant temperature variations, high pressures, transverse forces, and contact with hydraulic fluids, over time absolutely all cylinder seals will leak. Which, of course, reduces your machine performance. However this can be quite a simple fix, which involves resealing the cylinder. This is done in the workshop, and is a relatively quick and affordable repair.

We have literally resealed 1000s of cylinders. You can either give us a call and we can get one of our Hydraulic Techs out to bring the cylinder in, or you can bring it in yourself: 15 Macaulay St, Williamstown North.

A brand new seal is often the only thing standing between you and a perfectly operating machine.