Nobody has Spare parts right now – here’s what you can do

Let’s keep it simple! You have a hydraulic system that is driving/controlling a key money making asset in your business. Q: How long can you afford for it to be out of action?

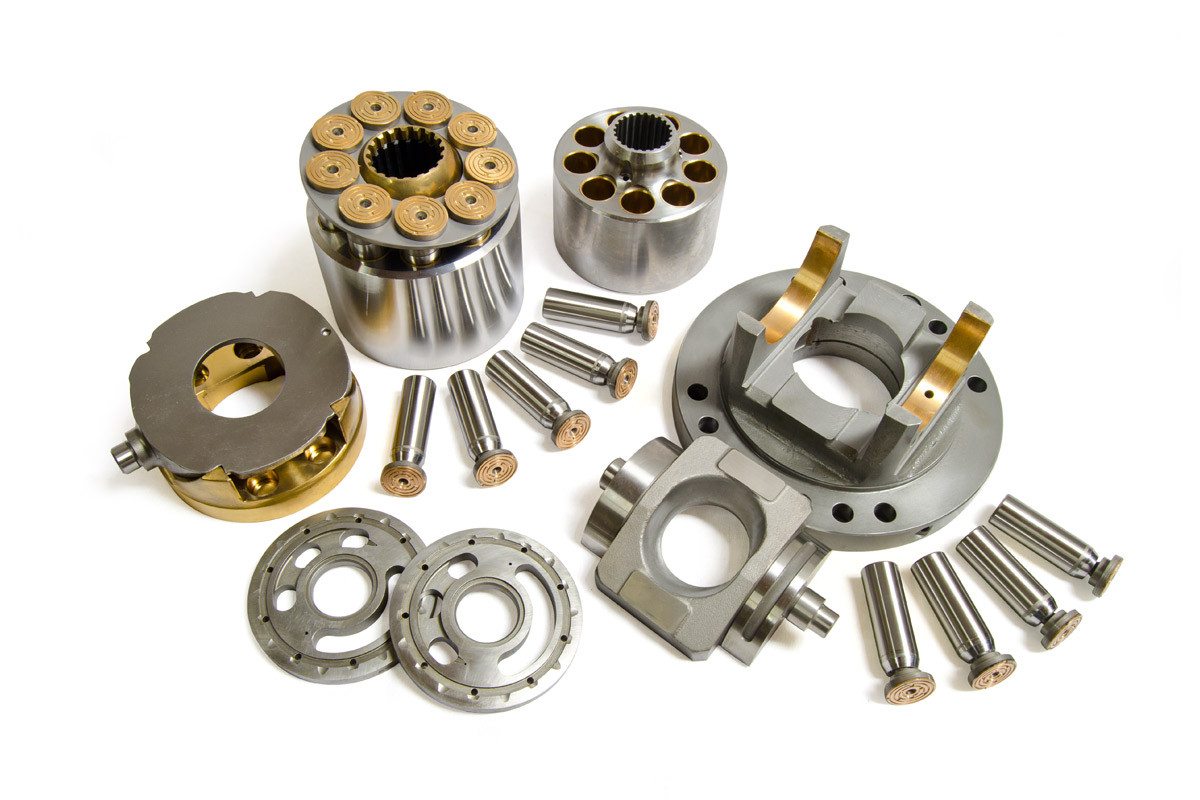

We all carry a spare tyre in our car, why not carry spares for our machinery?

With global supply chains being what they are right now, it can be incredibly difficult to get spare parts for hydraulic equipment. Even paying for airfreight, it can take up to 10 days. And trying to manufacture locally can take even longer.

Whether it be a $25,000 or $500 pump, the costs associated with loss of production as you wait for a new part to arrive, or having to modify an assembly due to the unavailability can be huge. We have seen it cripple some businesses. A vital production asset fails and a massive investment of resources and stress is required to get the machine back into service.

Because many stockists are not taking on the responsibility of carrying critical spares, and global manufacturing and supply chains are so slow, now is the best time to invest in stocking critical spares. It can mean a simple 2-3 hour replacement, rather than 7-10 days down time.

Thankfully we have a solution...

One of our Hydraulic solutions specialists can come to your site to identify the critical spares that should be stocked. This will mean you avoid potentially costly loss of production due to long lead times of critical components. For example, a simple coupling between the pump/motor for $95 kept as a spare part can save days of production time.

Flotek are the experts at getting your machines moving again.

Give us a call. We can have one of our hydraulics technicians out within 48 hours anywhere in greater Melbourne to identify your key spares. It may save your business thousands of dollars in machine downtime. Flotek also offers Scheduled Inspection Programs, which has a Technician on your site every 3 months to ensure your important production equipment will not break down.