Leaking Hydraulic Cylinder – What Is It Trying to Tell Me?

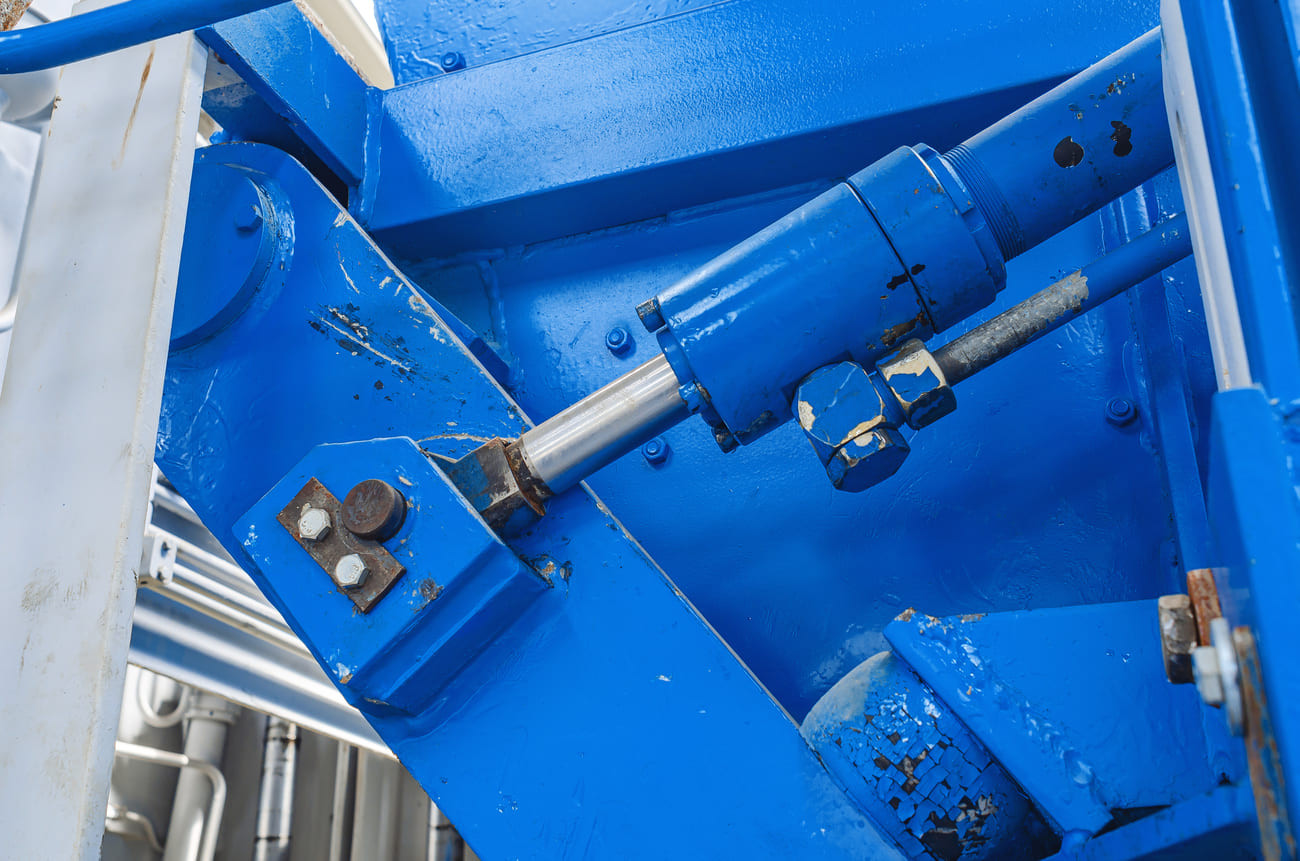

Hydraulic cylinders are crucial in mechanical systems, providing the force needed for lifting, pushing, and pulling. So when you start to see little leaks, it’s more than just a nuisance – your cylinders are trying to tell you something. So what are they trying to say, and why should you listen? Let’s look at the two types of hydraulic leaks, and what they really mean.

Two Types of Hydraulic Leaks

External Leaks: These occur when hydraulic fluid escapes from the cylinder's seals, connections, or fittings, and you can visibly see weeping of the oil on your machines.

Internal Leaks: the bypassing of fluid within the cylinder, typically between the rod and cylinder bore. This is tricky, as you may notice reduced performance, with no visible external fluid weeping.

BOTTOM LINE: Both types of leaks are bad for your machines.

What Leaking Hydraulic Cylinders Tell Me

1. Worn or Damaged Seals

Seals are essentially designed to prevent fluid leakage – but they do of course wear out due to:

Friction and abrasion caused by repeated movement.

Contaminants like dirt or debris in the hydraulic fluid.

Chemical degradation from using the wrong hydraulic fluids.

When seals degrade, fluid leaks externally or even bypasses internally, which effects your cylinder's ability to lift, push, or pull.

2. Rod or Cylinder Damage

A bent or scored cylinder rod will damage seals and create gaps through which fluid escapes. So what can cause damage to a rod?

Improper alignment of the hydraulic system.

Overloading the cylinder, i.e.

Corrosion or pitting caused by environmental factors.

A damaged rod not only leads to leaks but can also accelerate wear on internal components.

3. High Operating Pressure

Hydraulic systems are designed to operate within specific pressure ranges. If the pressure exceeds the cylinder's capacity, it can cause:

Seal blowouts.

Damage to the cylinder wall or fittings.

Premature fatigue of internal components.

High pressure is often a result of malfunctioning relief valves, or improperly calibrated systems.

4. Poor Maintenance Practices

Lack of regular inspection and maintenance can lead to leaks over time. Neglecting to:

Change hydraulic fluid at recommended intervals.

Replace worn components.

Address contamination in the system.

These relatively small issues, can become big problems if they’re not addressed.

5. Misalignment or Overloading

Hydraulic cylinders that are misaligned with the load, or subjected to excessive forces beyond their capacity are prone to stress-related leaks. Overloading will often cause both internal and external leaks.

So, What Can Happen When My Cylinders Are Leaking?

Ignoring a leaking hydraulic cylinder can have severe consequences, including:

Reduced Performance: Internal leaks lower the cylinder's efficiency, leading to slower operation or failure to move the load.

Increased Maintenance Costs: Small leaks, if left unattended, can cause extensive damage requiring more costly repairs or replacements.

Environmental Hazards: Leaked hydraulic fluid can pose environmental and safety risks, especially if the fluid is toxic.

System Downtime: Unaddressed leaks can escalate into complete system failure, leading to operational delays.

See the previous article explaining more: Fluid Leaks, the Silent Hydraulic System Killer

Addressing and Preventing Leaks

To address and prevent hydraulic cylinder leaks:

Regular Inspection: Check seals, rods, and cylinder bodies for signs of wear or damage. Flotek can provide a quarterly inspection program, which will identify the first signs of a leak.

Proper Maintenance: Follow manufacturer-recommended maintenance schedules, including fluid changes and component replacements. Flotek also carries out hydraulic oil replacement.

System Calibration: Ensure pressure levels are within the cylinder's rated capacity.

Quality Components: Use high-quality seals and components compatible with your hydraulic system.

Cleanliness: Keep hydraulic fluid free from contaminants.

Conclusion

A leaking hydraulic cylinder is a clear sign that something is amiss within the system. While the issue might seem minor at first, it can escalate quickly if ignored.