Flotek’s Reliability Inspection Agreement!

Embracing German technologies and latest fluid power knowledge from the international market leader and our partner in the field, Hydac, Flotek has evolved to become the leading hydraulic service company in Melbourne! Focusing on extending Machine Life Expectancy via Fluid Engineering.

Establishing ourselves here in Melbourne in 2005, we tend to provide top quality customer service, along with accurate and reliable servicing and inspections.

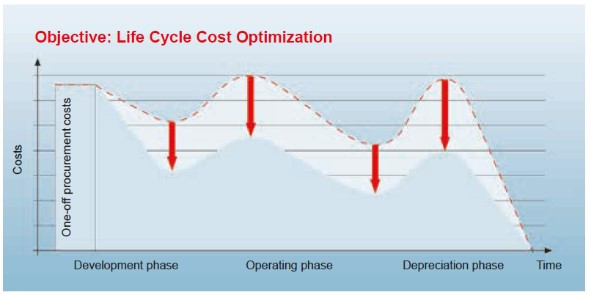

For example, centring heavily on reducing lifetime costs of machinery through maintaining integrity.

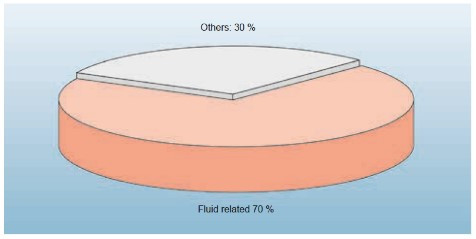

Flotek’s Fluid Engineering Expertise comes from our understanding of fluid in the hydraulic systems. The condition of the operating fluid plays a vital role in the Life Cycle Cost Optimization, knowing that approximately 70% of all breakdowns of hydraulic and lubrication systems can be attributed to the condition of the fluid in the system – with proven detrimental effects on the efficiency and profitability of systems and equipment. With Flotek intending on minimising the breakdowns.

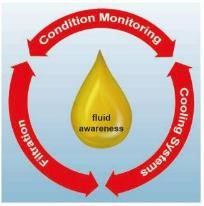

Once the relationship between the fluid condition and the profitability of the systems is recognized, the obvious action required that Flotek pursues is:

Fluid Conditioning – which involves Fluid Condition Monitoring, Cooling and a well-engineered Filtration System. These will guarantee the efficient and operational reliability of the entire hydraulic or lubrication system.

What Flotek provides is a thorough inspection of each hydraulic system, that includes:

Overall system visual inspection – checking for damages, leaks, noise and vibration on all actuators, hoses, tubing, hydraulic components and the power units.

System operation parameters inspection – oil level, temperature, system pressure and hot spots according to design specifications.

Operating conditions observation – system functions and functional test, whenever machine is available.

Fluid analysis – onsite particle count, fluid saturation level analysis, fluid temperature measurement and bottle sample taken for 2nd verification in Flotek oils analysis lab or a third-party lab. Onsite analysis is carried out while the machine is running.

Detailed inspection (job completion) and recommendation report.

All travel to-from your site

Regular inspections will provide details on the overall health and condition of the hydraulic system before something happens. Targeted follow up works can be carried out if required for those instances. Our hydraulic field technicians are all professional with years of experience, for more information – Please feel free to contact us!